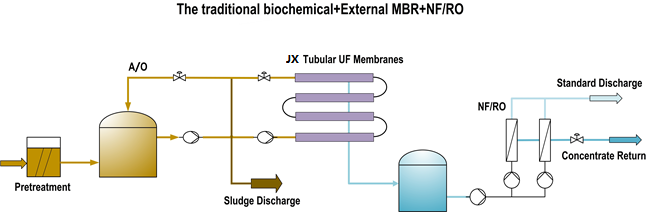

In the global energy sector, finding efficient and reliable Tubular UF membrane technology is crucial for improving power plant performance. Recently, our Tubular Membrane successfully replaced the Pentair TMBR Compact 33V model at a power plant in Africa, resulting in significant benefits. This success story not only validates the advanced nature of our technology but also showcases the immense potential of Tubular Membranes in practical applications.

The primary mission of the African power plant is to provide stable electricity supply to support regional economic development. However, the plant encountered several issues with the Pentair Compact 33V membrane components:

Durability Issues: The Pentair TMBR Compact 33V membranes exhibited rapid degradation under high-load operating conditions.

High Maintenance Costs: Traditional membrane components required frequent cleaning and maintenance, leading to increased operational costs.

Performance Instability: Under extreme conditions, the membrane’s performance significantly declined, affecting the stability of power production.

To enhance the overall system performance, we recommended replacing the Pentair Compact 33V with our Tubular Membrane. The following technical advantages were observed with Tubular Membrane in this project:

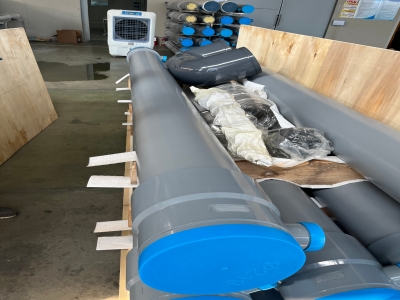

Enhanced Durability: Tubular Membrane utilizes advanced ceramic and polymer composite materials, ensuring stable operation under high loads and harsh environments. Our membrane components demonstrated superior durability, with an average lifespan 30% longer than the Pentair Compact 33V.

Lower Maintenance Costs: Compared to traditional membrane components, Tubular Membrane offers superior self-cleaning capabilities, significantly reducing cleaning frequency. This feature directly lowers maintenance costs and increases the economic benefits of the power plant.

Excellent Performance Stability: The design of Tubular Membrane ensures stable performance under varying operating conditions. Even in high temperatures, high salinity, or high pollution water conditions, the membrane’s filtration performance remains consistent. This stability effectively improves the overall operational efficiency and reliability of the power plant.

Significant Energy and Emission Reduction: The high-efficiency filtration capability of Tubular Membrane reduces wastewater and chemical usage, contributing to lower environmental impact and energy consumption.

Since the installation of Tubular Membrane, the African power plant has made notable progress in several areas:

Performance Improvement: The replacement of the membrane component resulted in a 20% improvement in performance, significantly enhancing the power plant’s electricity production efficiency.

Operational Cost Reduction: The reduction in maintenance and replacement frequency led to a 15% decrease in overall operational costs.

Reduced Environmental Impact: The use of the new membrane component reduced wastewater and chemical emissions, helping the power plant better comply with environmental protection regulations.

Membrane Flux: The standard flux of Tubular Membrane is 30 L/m²·h, which is a 20% improvement over the Pentair Compact 33V.

Temperature Range: Our membrane components operate stably within a temperature range of -5°C to 60°C, whereas the Pentair Compact 33V has a temperature range of only 0°C to 45°C.

Membrane Materials: Tubular Membrane uses high-strength polymer and ceramic composite materials, while the Pentair Compact 33V primarily employs traditional polyamide materials.