Author: Site Editor Publish Time: 2023-04-20 Origin: Site

The MBR membrane bioreactor is a new type of treatment process. Compared with the traditional process, it has the characteristics of a small footprint, good effluent quality, and low operating cost. It is one of the hotspots in wastewater treatment and has wide applications.

Membrane Bio-Reactor (MBR) is a new type of wastewater treatment system which organically integrates membrane separation technology and biological treatment technology. The membrane module replaces the end secondary sedimentation tank of traditional biological treatment technology, maintains a high activated sludge concentration in the bioreactor, improves the organic load of biological treatment, thus reduces the area of sewage treatment facilities, and reduces the amount of residual sludge by maintaining a low sludge load. Activated sludge and macromolecular organic matter in water were intercepted by membrane separation equipment. The concentration of activated sludge (MLSS) in membrane bioreactor system can be increased to 8000~10,000mg/L or even higher. Sludge age (SRT) can be extended to more than 30 days.

MBR is a new and efficient separation technology, a new process combined with the traditional activated sludge method. It is a unique structure MBR membrane module placed in the aeration tank. After aerobic aeration and biological treatment, the water is pumped through the filter membrane and then pumped out. It uses an MBR membrane to intercept the activated sludge and macromolecular organic substances in the biochemical reaction tank without needing a secondary sedimentation tank. Therefore, the concentration of activated sludge is greatly improved, and it can control the hydraulic retention time (HRT) and sludge retention time (SRT) separately. At the same time, the refractory substances are continuously reacted and degraded in the reactor.

1. Degradation of organic matter in sewage, nitrifying bacteria nitrate Nspan-N into NO3-, and the removal rate of organic matter is above 95%; The removal rate of ammonia nitrogen is more than 97%

2, the pretreatment process is simple, no need to add a large number of chemical agents, simple operation process;

3, high recovery rate, water recovery rate can reach more than 99%, this flexibility allows the operator in the inflow of unpurified water quality deterioration by reducing the recovery to reduce the "pressure" on the diaphragm, but at the same time to produce the same total and quality of purified water;

4. The system uses logical processes to monitor the system, including traffic transporters and pressure transporters. This highly controlled system approach can be used to design flexible systems and improve the low requirements of operator interfaces;

5. Air washing ensures reliable operation under various inflow conditions;

6. Automatic recoil ensures that the overall film flux is increased at a lower membrane pressure;

7, the floor area is small, only 10 ~ 20% of the traditional technology;

8, long service cycle, continuous operation time up to 70,000 hours, broken wire rate is less than 1%.

The advantages of our MBR membrane.

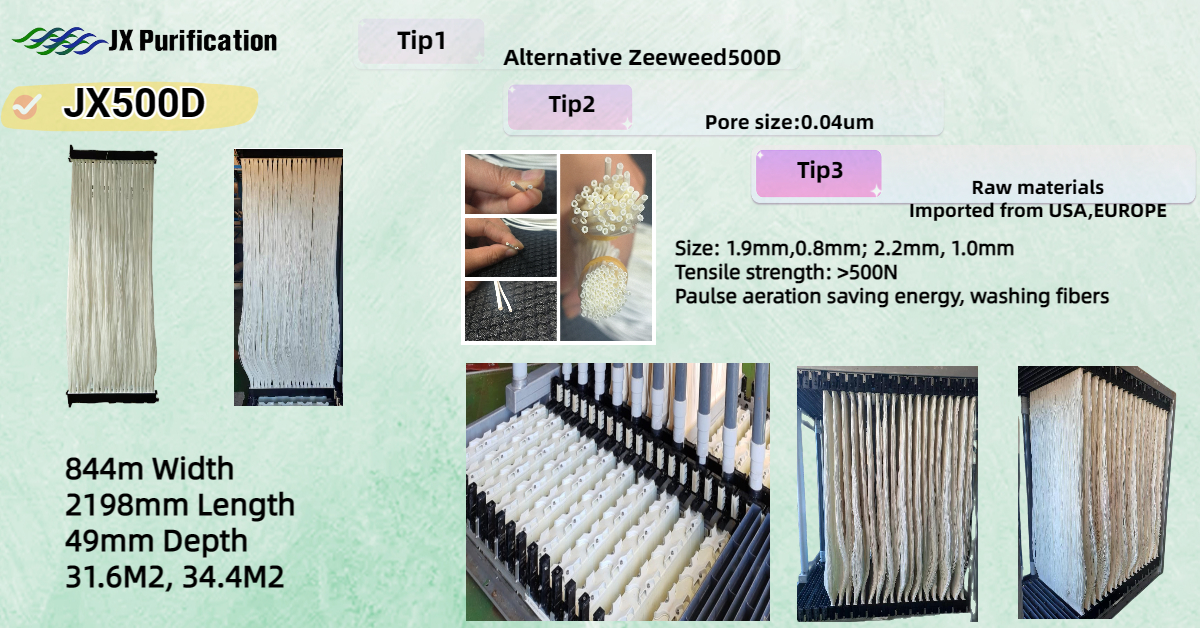

We can supply : Suez zeeweed 500D membranes analogue, Mitsubishi 5000, 5600 alternative, Our own design Mbr membranes.

1.Large-scale municipal wastewater treatmentreuse of reclaimed water

in the community, reuse of reclaimed water in department stores and

office buildings.

2.Wastewater treatment and reuse in restaurants or scenic spots

3.Surface-water purification treatment.

4. Various beverage factoriesdistilleries,foodlivestock

slaughterhouses, dyeing and finishing, leather paperand pulp

factories wastewater treatment.

The above is the information about the MBR membrane bioreactor and its

working principle &applications. If you still have related questions about the

membrane bioreactor, please feel free to contact JX-Purification.